|

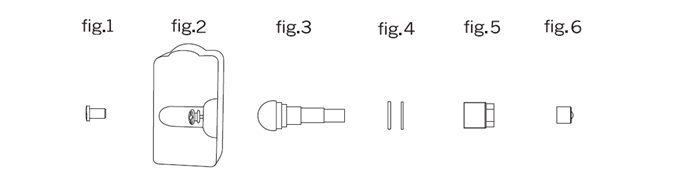

| 1 | Clear valve stem hole in rim of any corrosion or dirt. Ensure there is a clean smooth surface or the mating of the TPMS sensor screw ( fig.1 ), rubber washer and valve core assembly ( fig.3 ), TPMS washe ( fig.4 )r, and TPMS nut ( fig.5 ) to the rim. |

| 2 | Remove TPMS sensor screw ( fig.1 ), washer ( fig.4 )and nut ( fig.5) from TPMS sensor value stem assembly. |

| 3 | While holding TPMS sensor body ( fig.2 ), the plastic side of TPMS sensor facing the tire , push TPMS sensor value stem ( fig.3 )through rim by hand until TPMS rubber washer ( fig.3 ) meets inside edge of rim. |

| 4 | Lock the TPMS sensor ( fig.2) and TPMS sensor value stem assembly together by screw ( fig.1 ). |

| 5 | Hold TPMS sensor body ( fig.2 )down against the rim drop center and thread/tighten TPMS sensor washer ( fig.4)and nut ( fig.5 )to 35 inch-pounds or 4..0 newton-meters. |

| fig.1 | TPMS sensor screw | fig.2 | TPMS sensor ( mounted inside wheel ) |

| fig.3 | TPMS sensor valve stem,rubber washer and valve core assembly |

fig.4 | TPMS washer ( mounted outside wheel ) |

| fig.5 | TPMS sensor nut ( mounted outside wheel ) | fig.6 | TPMS sensor cap |

each time a tire is serviced or dismounted, or if the TPMS sensor( fig.2 ) is removed, it is MANDATORY to replace the TPMS sensor washer( fig.4 ) , TPMS sensor nut( fig.5) , and TPMS sensor valve core ( fig.3 ) with CUB parts to ensure proper sealing. It is MANDATORY to replace the TPMS sensor if it is externally damaged. |

| NOTE use only CUB service component kits designed for TPMS sensor. |

Warning: The TPMS sensor nut must be properly installed and tightened for proper installation. Carefully follow instructions and use a torque wrench to ensure proper installation. Failure to torque the TPMS sensor nut properly will void the warranty and TPMS may not function properly. |

correct TPMS sensor nut torque: 35 inch-pounds; 4.0 Newton-meters, |